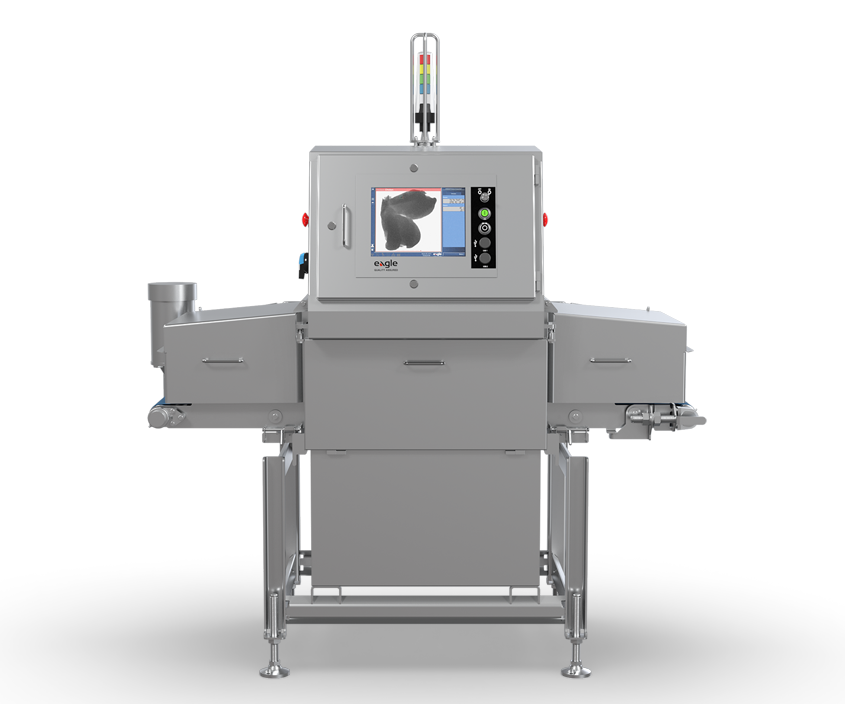

Unparalleled Detection

PXT™ is a breakthrough detector that delivers a quantum leap in x-ray inspection performance. The PXT™ photon-counting detector captures more detailed usable data about the product being inspected than has previously been possible – providing the unmatched ability to detect metal and bone at different stages in your production process.

.svg)