All the Power of Two Sets of X-ray Energies

MDX dual energy technology, measures the ratio of two different sets of x-ray energies that pass through a product and this measurement enables organic and inorganic materials to be differentiated, providing food processors with unprecedented contaminant detection capabilities.

Food processors worldwide have been relying on Eagle’s superior dual energy technology for more than 15 years. Originally pioneered for use in the security sector, MDX was developed to detect foreign bodies previously unseen by x-ray or other conventional inspection technologies in product applications that produce busy x-ray images.

Single Energy vs Dual Energy

There are two types of x-ray inspection technologies available for product inspection: single energy and dual energy. While it is true that dual energy offers more detection accuracy and sensitivity when inspecting products, there are certain factors to be considered to determine if dual energy is the right inspection technology for your specific application such as:

- Likely contaminant

- Product

- Packaging Type

- Production speed

- Customer Specifications

This white paper illustrates the advantages and disadvantages of both x-ray technologies using real application examples. Find out if dual energy is right for you!

Helping You Meet Safety and Compliance Standards

Eagle helps ensure the safety and integrity of your products. Staying compliant with regulations strengthens your brand reputation and streamlines operational efficiencies.

Protect Brand & Reputation

Catching contaminants and removing “faulty” products before they leave the facility is a cost-effective solution to avoid product recalls, customer complaints and adverse publicity.

Manage Risk & Ensure Regulatory Compliance

Equipment technologies on your line will adhere to compliance programs, including HACCP, GFSI, BRCGS, IFS, SQF and FSSC.

Improve Production Efficiency

Eagle supports our customers’ journey to world-class Overall Equipment Effectiveness (OEE) status and Total Effective Equipment Productivity (TEEP) measurement with inspection technology that minimizes giveaway and maximizes throughput for enhanced effectiveness.

Industry Resources

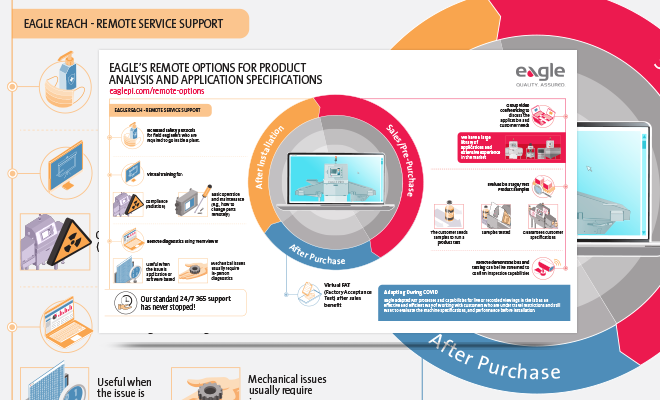

3 Types of Remote Support Options for X-ray Inspection

What are the three types of remote support options for x-ray installation and equipment use to ensure manufacturers stay compliant with food safety standards?

5 Reasons to Invest in X-ray Inspection for Quality Assurance

What are the key motivators for investing in x-ray product inspection and how can it improve your bottom line?

Carton Red Meat Products

The Eagle™ Pack 720 PRO with MDX technology maximizes efficiency and product yield of red meat processor lines with x-ray inspection of incoming bone-in and boneless meats packaged in frozen cartons.

Cheese Blocks

X-ray inspection equipment ensures final cheese blocks are contaminant free and accurate weight.

.svg)