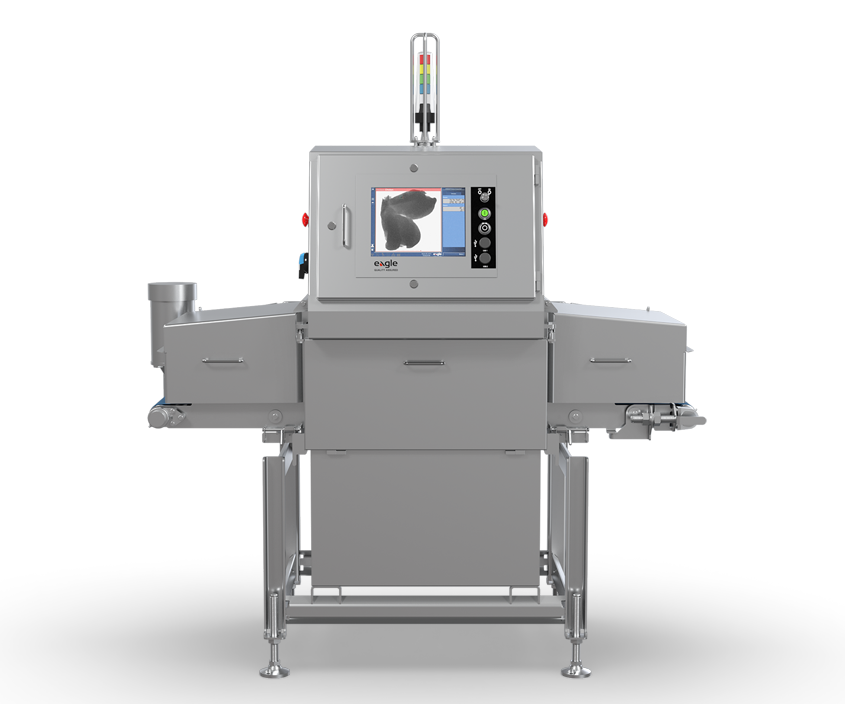

Sistemas de raios X proporcionar uma detecção superior

Combinação do melhor desenho de máquina física da classe com gerador e detector múltiplos e SimulTask™ PRO software de imagem, obtém a melhor solução para a sua linha de produção. Eagle oferece múltiplas configurações e tamanhos de detectores com opções de díodos para se adaptar às suas necessidades específicas e requisitos de aplicação, proporcionando uma detecção superior de contaminantes físicos dos seguintes contaminantes:

- Vidro

- Fragmentos de metal

- Pedra mineral

- Osso calcificado

- Alguns compostos de plástico e borracha

Detecção de Contaminantes Corpo Estrangeiro

Detecção óssea

Detecção de pedras

Detecção de vidro

Detecção de metais

Detecção de Plástico

Detecção óssea

Detecção óssea

Os sistemas de raios-X de águia são capazes de detectar até 2 mm de ossos, mas quando emparelhados com o novo detector PXT™ as nossas máquinas podem localizar fragmentos de ossos até 1 mm em produtos de aves de capoeira e .5 mm em filetes de peixe. Localizar os mais pequenos fragmentos de ossos em frango, peixe e produtos de carne vermelha com análise de imagem de alta resolução para resultados fiáveis e menos rejeições falsas.

Detecção de pedras

Detecção de pedras

Os contaminantes das pedras podem representar vários riscos de segurança e os sistemas de inspecção de energia dupla da Águia permitem uma excelente detecção de pedras, particularmente em alimentos com várias texturas, tais como nozes e cereais misturados. Veja como o Eagle Bulk 415 PRO com tecnologia MDX de dupla energia discrimina facilmente entre produto de figo e pedras que são misturadas na colheita mas que passariam despercebidas a olho nu.

Detecção de vidro

Detecção de vidro

As embalagens de vidro aumentaram em popularidade e são utilizadas para uma vasta gama de aplicações. Mas as embalagens de vidro representam um risco de segurança significativo e os efeitos da contaminação de vidro em vidro podem ser altamente prejudiciais. O sistema de inspecção de quatro vistas da Eagle detecta pequenos contaminantes de vidro nas paredes laterais e fendas inferiores de recipientes rígidos altos que salvaguardam os produtos alimentares e a reputação da marca.

Detecção de metais

Detecção de metais

Os sistemas de raios-x Eagle são capazes de detectar metais numa vasta gama de aplicações e tipos de embalagem. Ao contrário dos sistemas de inspecção tradicionais, o raio-x pode ver directamente através de folha de baixa densidade ou filme metalizado para obter uma melhor visão dos contaminantes metálicos. Descubra como as máquinas de inspecção por raios X podem reduzir a sua taxa de rejeição falsa e optimizar a sua linha de inspecção de produtos para obter o máximo de resultados.

Detecção de Plástico

Detecção de Plástico

Os sistemas de inspecção de raios X da águia são capazes de detectar alguns plásticos e borrachas. Contudo, a tecnologia de dupla energia (MDX) é frequentemente mais adequada para a detecção de plástico, particularmente em produtos alimentares a granel e embalados, como sacos de folhas de salada mistas, cereais, frutos secos e confeitaria, todos eles contendo grandes variações na densidade.

Resultados fiáveis para A sua linha de produção

CONSISTÊNCIA

FIABILIDADE

TEMPO DE PARAGEM REDUZIDO

MAIOR PRODUÇÃO

QUALIDADE SUPERIOR DO PRODUTO

MENOR CUSTO DE PROPRIEDADE

DESIGN HIGIÉNICO

Inspecção de produtos Avançado

Inteligência superior. Resultados superiores.

O software avançado de análise de imagem SimulTask™ PRO elimina as suposições das imagens de raios X para se concentrar em segurança, qualidade, eficiência operacional e lucratividade.

Quão segura é a inspecção por raios-X?

Descubra como o equipamento de raios X oferece inspeção de produto segura e eficaz com resultados repetíveis e confiáveis para uma grande variedade de contaminantes.

Fale com UM EXPERTADOR

Pedir uma citação

Preencha o formulário com os detalhes da inscrição e um representante entrará em contato com você.

"*" indica os campos obrigatórios

Eagle Indústrias

Carne Vermelha

Aves de capoeira

Frutos do mar

Lacticínios

Frutas e legumes

OEM & Integradores de sistemas

Carne Vermelha

Carne Vermelha

A Eagle reconhece a importância de utilizar os sistemas mais robustos e higiénicos de inspecção de carne e análise de gordura, fáceis de gerir, e que se possam adaptar à sua linha de produtos única. A partir da gestão de receitas para produtos moídos com FA ou da inspecção de caixas para enchidos, os nossos sistemas de inspecção de carne vermelha fornecem resultados precisos e fiáveis que são alcançados de forma consistente nas linhas de processamento, independentemente dos níveis de produção e dos ambientes.

Aves de capoeira

Aves de capoeira

Eagle fornece tecnologias avançadas de raios X e sistemas de inspecção para uma variedade de aplicações avícolas, desde a recepção do produto bruto de fluxo a granel, passando pelo produto em processo até ao produto embalado final. As nossas máquinas de raios X de construção higiénica são adequadas para uma variedade de aplicações avícolas. Descubra a nossa vasta gama de soluções com desempenho comprovado significativo para a detecção superior de ossos e outros contaminantes.

Frutos do mar

Frutos do mar

Apanhar e remover contaminantes antes que estes coloquem problemas com o equipamento de construção higiénica da Águia. Os nossos avançados sistemas de inspecção e tecnologias inovadoras PXT™, ajudam os fabricantes de produtos do mar a inspeccionar mais, assegurando uma qualidade superior ao mesmo tempo que optimizam o desempenho empresarial. As aplicações incluem filetes ou blocos de peixe congelado, sacos enlatados ou metalizados e produtos descascados a granel.

Lacticínios

Lacticínios

Os sistemas avançados de inspecção da Águia cumprem as normas sanitárias 3-A e podem detectar contaminantes estrangeiros numa grande quantidade de produtos lácteos, desde blocos de queijo cru a iogurtes embalados. O nosso equipamento higienicamente construído de acordo com a concepção sanitária pode também assegurar o porcionamento adequado, a colocação do produto, o peso e a integridade da embalagem para fornecer os produtos mais seguros e da mais alta qualidade.

Frutas e legumes

Frutas e legumes

Quer seja a detecção de fragmentos de vidro em frascos de vidro de geleia, plástico num saco de milho congelado ou metal no fundo de um frasco de vegetais em conserva, os sistemas de raios-x Eagle permitem uma detecção notável. Com tecnologia avançada de energia dupla os nossos sistemas podem detectar contaminantes em alimentos densos, tais como frutos secos a granel, e gerar imagens de fácil leitura para uma análise melhorada.

OEM & Integradores de sistemas

OEM & Integradores de sistemas

Eagle é uma marca digna de confiança, empenhada em construir tecnologia e equipamento de inspecção por raios X com integridade. Orgulhamo-nos do nosso sucesso comprovado em várias indústrias com resultados fiáveis e repetíveis. Não vendemos apenas máquinas; construímos relações duradouras para assegurar que a sua base de clientes é bem servida. Saiba mais sobre os benefícios de escolher a inspecção de raios X da Eagle para os seus clientes.

As 10 perguntas mais frequentes para a inspecção por raios X

Obtenha respostas às perguntas mais frequentes para a inspecção de produtos com raios X! Descubra como as máquinas de raios X da Eagle combinadas com o nosso sofisticado software fornecem as imagens de maior resolução da indústria com a maior quantidade de detalhes para uma detecção fiável.

Saiba como a combinação de construção robusta e higiénica e software avançado permitem uma vasta gama de detecção para evitar a recolha de produtos, poupando tempo e trabalho dos processadores nas suas linhas.

Recursos de la Indústria

Guia de produtos Eagle

O nosso guia de produtos apresenta cada um dos nossos sistemas de análise de gordura e raio-x, juntamente com as suas capacidades específicas, e foi concebido para ajudar os fabricantes a encontrar a solução óptima para as suas necessidades individuais.

60 SEGUNDOS DE SERVIÇO – COMO ASSEGURAR O DESEMPENHO DO EQUIPAMENTO

Descubra porque é que investir em pacotes de serviços para a sua máquina de raios X significa melhores resultados a longo prazo tanto para a sua produção como para o seu resultado final.

Amêndoas não embaladas

Descubra como a tecnologia MDX proporciona aos processadores de amêndoas uma maior precisão de detecção.

Até que ponto é segura a inspecção de alimentos por raios-X?

Destruição de conceitos errados sobre a inspecção dos alimentos por raios X.

.svg)