Every packaged good must be weighed before distribution to ensure it is within company and industry specification. While selling underweight products can lead to companies being fined or subject to other penalties, overweight products generate unnecessary and expensive product giveaway. Many industries rely on a high-precision weight measuring instrument known as a checkweigher as part of an effective quality assurance system. In addition to assisting manufacturers in meeting local weights and measures regulations for package weight compliance, checkweighers help to ensure delivery of quality products that promote high levels of customer satisfaction, but there are different types of checkweighers including x-ray systems for food inspection.

Types of Checkweighing

Gravimetric checkweighers and x-ray inspection systems are both popular forms of checkweighing used in food manufacturing today.

Gravimetric checkweighers use the earth’s gravitational pull to convert the mass of the package into a calibrated electrical signal by using an electro-mechanical sensor called a weigh cell or load cell, which is then converted into a weight value. The weight value is displayed digitally on the checkweigher user interface and that value is also used to determine the classification of the package as an accepted or rejected product.

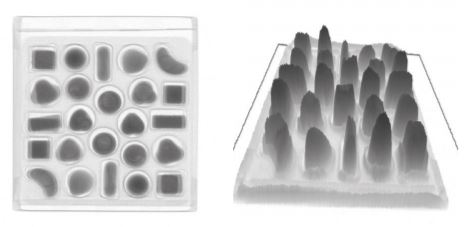

X-ray systems for food inspection also provide 100% inline checkweighing. They determine mass by measuring the absorption values (often referred to as the grey-scale or grey tones) of the inspected item. The grey tones enable the creation of a 3D product image allowing the system to deliver a volumetric measurement used to determine its mass and weight value.

Read our white paper “Why Using X-ray Systems for Checkweighing is a Smart Choice” to learn more.

Both types of checkweighing provide manufacturers with a valuable tool to help ensure compliance with minimum weight, EU average weight or USA net contents regulations. However, x-ray systems can see and measure more than just package mass. They simultaneously count components, inspect multi-compartment packages, identify broken, damaged or missing items, as well as inspect for foreign body contaminants all at high speeds,providing enhanced quality assurance and overall brand protection.

1. X-ray systems for Counting Components

Unlike conventional checkweighers, x-ray systems for food inspection can look inside final sealed packaging and analyze the contents independently of the packaging. This ability means systems can simultaneously measure mass and check that all components are present.

Take a box of chocolates for example, the weight variability of each chocolate type or the inadvertent filling of two chocolates in one compartment can lead to a condition where one compartment is missing a chocolate even though the entire package weight remains within the overall weight tolerance value. A gravimetric checkweigher won’t know that there’s an empty compartment and will pass the box as correct based on its overall weight.

Additionally, a pack of five sausages may weigh the same as a pack of six. In this instance, a checkweigher won’t know the difference because the package falls within the weight tolerance. However, by looking inside the packaging and spotting the missing sausage, an x-ray system for food inspection can help to increase customer satisfaction at a more accurate level.

2. X-ray Systems for Inspecting Multi-compartment Packages

As well as delivering accurate and reliable overall mass measurements to satisfy the need for gross package checkweighing, x-ray systems can measure mass within individual zones or compartments. This ability allows manufacturers to spot packs where the overall weight is correct, but there’s low fill in one of the compartments. For example, a dessert pudding or a macaroni and cheese side item in a ready-meal tray may have a low fill level and this can be detected by x-ray inspection technology. In contrast, gravimetric checkweighers can’t identify under filled compartments and will therefore accept packs if the entire package is within the overall acceptable package weight value.

3. X-ray Systems for Identifying Broken, Damaged or Missing Items

X-ray systems are also capable of identifying and rejecting packages that meet the target weight criteria but contain broken or damaged contents. Gravimetric checkweighers, on the other hand, can only determine if the weight is correct, they can’t determine if the contents are pristine or have been damaged. This means that a box containing broken crackers will be accepted by a gravimetric checkweigher because it has the appropriate content weight, but rejected by an x-ray system due to the image showing a broken cracker which is an unacceptable quality condition. Read how Compania de Galletas Noel uses x-ray technology to reject broken crackers from reaching final customers.

4. X-ray Systems for Inspecting High speed Applications

Gravimetric checkweighers offer good accuracy at low packs per minute rates, but as line rates increase, degradation in delivered accuracy occurs. In contrast, x-ray systems for food inspection produce a precise weight count at faster speeds in comparison to gravimetric checkweighers.

Still not convinced? Watch our Webinar, ‘Why is Using X-ray Systems for Checkweighing a Smart Choice?‘, to learn about it first-hand from one of our Eagle experts.

.svg)